AsphaltPro Magazine

March 2016

THE BARRELMOVER 5000

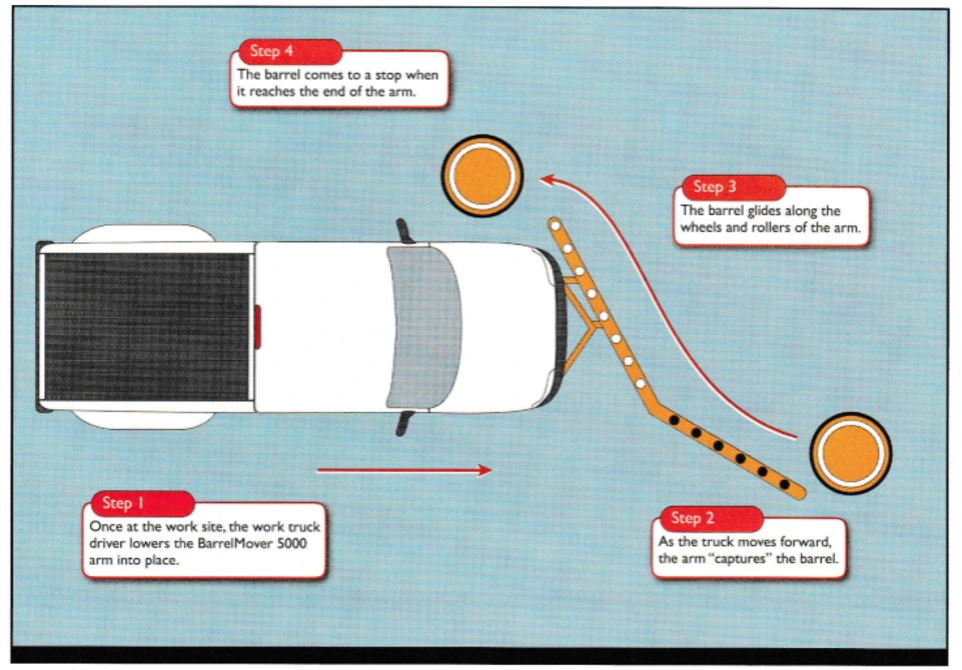

No matter the size of your project, getting the safety barrels back and forth at the beginning and end of each shift opens personnel up to hazards. Kyle Ruby, inventor of the new safety item from BarrelMover 5000, Dry Ridge, Kentucky, lessens the danger to workers by taking them off the road with the BarrelMover 5000. Here’s how it works.

Before work begins, the mechanic will replace existing tow hooks on any Ford, Chevrolet, GMC or Dodge work truck with the Barrel Mover 5000 mounting brackets. Once at the work site, the driver follows a set of three steps to lower the Barrel Mover 5000 completely-welded frame from transport mode into working mode, offsetting it from center to the left or right depending on the arrangement of the work zone.

With the spring-loaded mainframe in place, the worker drives the truck forward at 10 to 12 MPH.

From the safety of the driver’s seat, he can watch the arm contact and move barrels through an optional magnetic-mounted camera and in-cab screen.

A specially designed hook attachment comes into contact with the barrel with minimal impact to the barrel, and directs the moving barrel along the wheels and rollers of the arm. When the barrel reaches the end of the arm, it comes to rest at the edge of the work zone in line with previous barrels, delineating the work zone.

LED safety lights on the ends of the mainframe offer additional safety, delineating the equipment passing motorists.

Depending on the size of the work zone to be protected, the operator can add an optional 12-foot attachment to extend barrel logistics to two lanes

-By Asphalt Pro Staff

PavingPro Magazine

August 2016

The BarrelMover 5000 Moves Barrels Safely, Efficiently

When Monty Richmond, director of human resources and safety at Brooks Construction Company, Inc., Fort Wayne, Ind., learned about the BarrelMover 5000 in an issue of Asphalt Pro Magazine, it didn’t take him long to act.

According to BarrelMover5000’s sales manager, Dave Wyrick, Richmond contacted the company online and they met at World of Asphalt 2016. Soon after, Brooks Construction purchased the BarrelMover 5000, which is a truck attachment that moves barrels from lane to lane safely and efficiently.

“Just the other day a worker was hit moving barrels,” said Kyle Ruby, inventor of the BarrelMover 5000. The worker was struck by a pickup truck in a construction zone on Interstate 469 in Indiana, just east of U.S. 27. “That’s one of the reasons I invented [the BarrelMover 5000]—to prevent things like that from happening.”

Brooks Construction uses the BarrelMover 5000 on multiple jobs in the same day on both right and left shoulders, and says it frees up two extra workers and improves safety.

“Worker site safety is the number one priority for Brooks Construction,” said Margaret Brooks, project superintendent at Brooks Construction Company, Inc. “The BarrelMover 5000 enables us to adjust lane closures safety and efficiently. We’ve seen reduced time and costs related to maintenance of traffic, and more importantly, our crews are better protected when moving barrels.”

Reviewer’s name & title: Project Foreman Doug Moulton

Company’s name: Brooks Construction Company, Inc.

Company town and state: Fort Wayne, Indiana

Name/make & model of equipment being reviewed: BarrelMover 5000

In what year did the company purchase the equipment? 2016

About how many hours does the equipment have in the field? Less than 300

Do you have a single operator or are multiple crewmembers trained in its use? Multiple operators

What do you think is the most useful feature of this product for your crew? It’s easy to set up and use. It is important because it saves us time and money.

Tell me how using this product has helped your business move forward. It saves time putting up and taking down a lane closure, which allows our people to move on to other aspects of the project. It is much safer for our employees to work on the lane closures.

Use this to move barrels.

For more information, contact Dave Wyrick or Clark Nowland at (859) 428-7411.